Aboust us

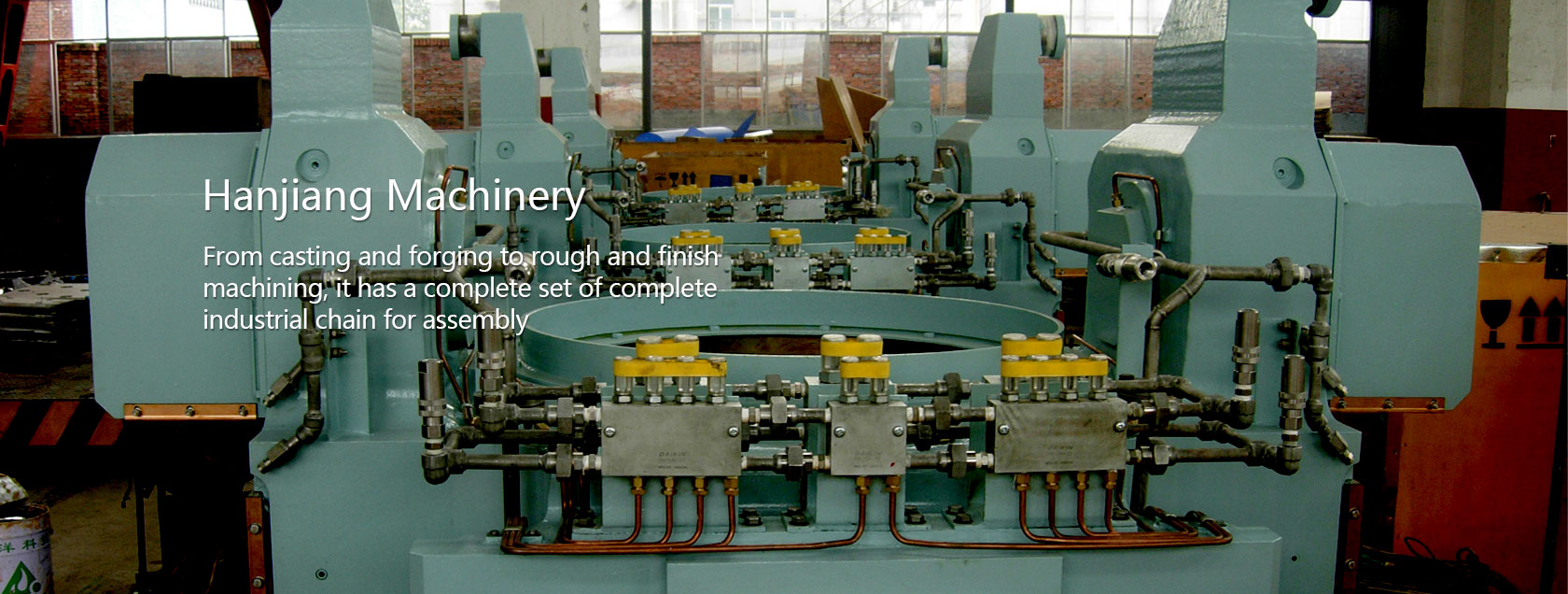

Deyang Hanjiang Machinery Manufacturing Co., Ltd. was established in 1986. Through more than 20 years of development, our company has developed into a medium-sized modern management group enterprise, with 381 employees, including 60 senior title managers, 25 senior title technicians and 35 intermediate title managers and technicians. The company has developed from a small workshop to a wholly-owned Hanjiang Machinery Company The factory, Deyang Wanhong Heavy Forging Co., Ltd., and shares in the group enterprise of Deyang YaoFa Heavy Casting Co., Ltd., has formed a complete industrial chain in the machinery manufacturing industry from casting and forging to rough and finish machining, and has a complete set of assembly sets.

The company now has 20 tons of electric arc furnace, 60 tons of ladle refining furnace, 1600t hydraulic press, 120t annealing furnace, 80t heating furnace, 2T air hammer, 10t operating machine, CNC gmb3000 × 8000 boring and milling machine, digital display wd200 floor boring machine, digital display tx6213a floor boring machine, digital display t6113 boring machine, t6112 boring machine, T160 boring machine, CNC 4m vertical lathe, c534 vertical lathe, c525 vertical lathe, sr1250 × 8000 horizontal lathe, c61160 × 5000m horizontal lathe There are more than 60 sets of rough and finish machining equipment, such as C640 sleeper, Z3063 rocker drill, etc., and the production and assembly site is nearly 25000 square meters. It has formed a large and medium-sized casting, rough and finish machining and assembly manufacturing base based on the main line of mill backup roll bearing seat, work roll bearing seat and medium-sized roll. The company is gradually moving towards the development road of scale, industrialization and collectivization.

Since 2001, our company has manufactured the upper and lower roller bearing block, vertical roller carriage, vertical roller, screwdown screw, screwdown nut and coiling aid roller body of 800 rolling mill production line for Tangshan Jianlong Industrial Co., Ltd., the upper and lower backup roller bearing block (5.5 tons per unit weight) and forging upper and lower working roller bearing block for 1700 rolling line of Kunming Iron and steel company, and the upper and lower working roller bearing block for Shanghai forging plant Spare parts for 2500kN hot die forging equipment, such as flywheel, gear shaft, clutch friction plate, etc.; nearly 20 upper and lower backup roll bearing blocks (7.8-10t) and work roll bearing blocks have been produced for Shougang 3500 rolling mill, WISCO 2250 finishing line, Hunan Lianyuan 1750 rolling line and 1780 stainless steel rolling line of No.1 plant of Shanghai Iron and Steel Co., Ltd.; and nearly 20 upper and lower backup roll bearing blocks and upper and lower backup roll bearing blocks have been manufactured for Chuanwei 950 finishing line and Xingtai 850 rolling line For 1780 rolling mill of Bayi Iron and Steel Co., Ltd., 3800 rolling mill of Xinyu Steel Co., Ltd., 2250 rolling mill of Austria iron and Steel Co., Ltd. (Poland), the bearing pedestal of backup roll and work roll (the heaviest single piece is 26.5 tons); for 1680 rolling line of Guangzhou Zhujiang iron and Steel Co., Ltd., three sets of front upper and lower pinch rolls of coiler are manufactured; for 1450 rolling line of Panzhihua Iron and Steel Co., Ltd., the complete sets of straightening roll and conveying roll table are produced It has manufactured straightening roll, gear shaft, gear frame and other parts for Guiyang Sanjhan Drilling Tool Co., Ltd.; it has produced Baosteel 5000 mill working roll and backup roll bearing pedestal (the heaviest single piece is 52 tons) for Erzhong Group Co., Ltd.; it has produced complete sets of equipment and spare parts for 2800 mill bearing pedestal and rail pedestal exported to mologo, Italy and other countries for ximak and Mitsubishi Heavy Industry Co., Ltd.

In recent years, our company has provided a large number of high-quality products for major steel companies and forging plants in China, and obtained ISO9001 quality certification within a few years. At the same time, our manufacturing capacity and technical level have been greatly improved. The company has transformed from a single entity into a modern entity joint-stock company integrating research, manufacturing, installation and maintenance.